Programming Techniques for PLC Controllers in Complex Industrial Processes

Core PLC Programming Techniques for Industrial Automation

Modular Programming Approaches for Scalable Systems

Modular programming is a vital technique in PLC automation, offering numerous benefits such as improved reusability and easier debugging. By dividing complex PLC systems into smaller modules, we facilitate faster development and maintenance, allowing each module to be updated or replaced independently without affecting the entire system. In practice, methodologies like function blocks and libraries empower programmers to create scalable PLC applications. Function blocks encapsulate specific functionalities, akin to reusable code components, enabling efficient and manageable automation solutions. Modular programming also enhances collaboration among development teams, as different developers can work on separate modules independently, thereby accelerating project timelines.

Implementing State-Based Logic in Process Control

State-based logic is essential for ensuring PLC systems respond appropriately across various operational states. This logic operates by defining states and transitions that represent specific conditions and actions within a process. Real-world examples can be seen in assembly lines where machines switch states between idle and active based on sensor inputs. For effective implementation, managing state transitions is crucial to avoid pitfalls like race conditions and deadlocks. Best practices involve thoroughly documenting state definitions and ensuring smooth logic flow between transitions. These strategies safeguard against system stability issues and foster responsive and adaptive process control in industrial environments.

Error Handling and Diagnostic Routines in PLC Code

Robust error handling is indispensable in PLC programming to maintain system reliability and safety. Implementing error detection mechanisms proactively identifies faults and ensures swift correction, thereby minimizing downtime. Diagnostic routines play a critical role, enabling quick identification of faults and guiding resolution efforts. Techniques such as implementing watchdog timers and error logging aid in diagnosing and resolving issues swiftly. Studies indicate that effective error handling can reduce downtime by as much as 30%, highlighting its significance in industrial automation. Through efficient error management, PLC systems enhance operational efficiency and uphold safety standards.

Advanced Motion Control and IoT Integration Strategies

Multi-Axis Motion Coordination Using High-Speed Pulse Outputs

High-speed pulse outputs play a crucial role in facilitating multi-axis motion control systems, enabling precise and synchronized movements in automation environments. The essence of these outputs lies in their ability to generate rapid signals necessary for accurate coordination between multiple axes. However, achieving seamless synchronization can be challenging due to complexities such as timing accuracy and potential signal delays. Techniques like PID control and feedforward control provide solutions by enhancing system responsiveness and stability. For instance, implementing these methods in an automated manufacturing setting can significantly increase both accuracy and productivity, resulting in more efficient operations and reduced waste.

Leveraging Industrial Ethernet Protocols for System Networking

The use of Industrial Ethernet protocols is advantageous for integrating PLCs and other devices within a network, offering robust connectivity and enhanced data exchange capabilities. Protocols like EtherCAT and Profinet are at the forefront, known for their superior performance metrics and real-time capabilities, making them ideal for time-sensitive applications. For example, EtherCAT's high-speed communication facilitates rapid data transfer, crucial in applications requiring immediate feedback and control. Companies adopting these networking strategies have observed marked improvements in operational efficiency and system reliability, demonstrating how these protocols contribute to streamlined automation processes and a more interconnected industrial environment.

Remote Management and Predictive Maintenance Capabilities

SD Card-Based Program Updates and Firmware Management

SD card-based updates revolutionize how we manage PLC firmware by offering simplicity and minimizing downtime. Implementing these updates allows manufacturers to easily transfer new programs without halting production, thereby maintaining seamless operations. However, with this convenience comes the responsibility of ensuring the security of SD card management. Best practices include encrypting data on the cards and using anti-tamper measures to protect the hardware and software integrity. Statistics underline these methods' benefits; for example, manufacturers have reported a 30% decrease in downtime thanks to streamlined firmware updates.

Web Server Integration for Real-Time Monitoring

Integrating web servers with PLC systems significantly enhances real-time monitoring, providing greater transparency and control over processes. This setup allows for instantaneous feedback on system operations, crucial for swiftly addressing any emerging issues. Implementation involves configuring the web server to interface with the PLC, knitting together a seamless network of real-time data exchange. The return on investment is compelling, with firms witnessing up to a 40% improvement in operational control and efficiency. Recent IoT trends highlight a surge in real-time data usage, aiding sectors from manufacturing to logistics in optimizing workflows and decision-making.

Implementing Predictive Maintenance Through Data Analytics

Predictive maintenance leverages data analytics to anticipate equipment failures, contrasting sharply with traditional reactive or preventive strategies. By continuously analyzing PLC performance, data analytics can foresee malfunctions, enabling preemptive actions that curtail costly downtimes. Industry statistics support this shift, showing that predictive maintenance can reduce maintenance costs by 25% and unplanned outages by 70%. Real-world examples include automotive plants using predictive analytics to monitor machinery health, resulting in significantly fewer disruptions and extended equipment lifespans. Embracing this data-driven approach is pivotal for any industry reliant on PLC automation systems.

Optimized PLC Solutions for Complex Automation Needs

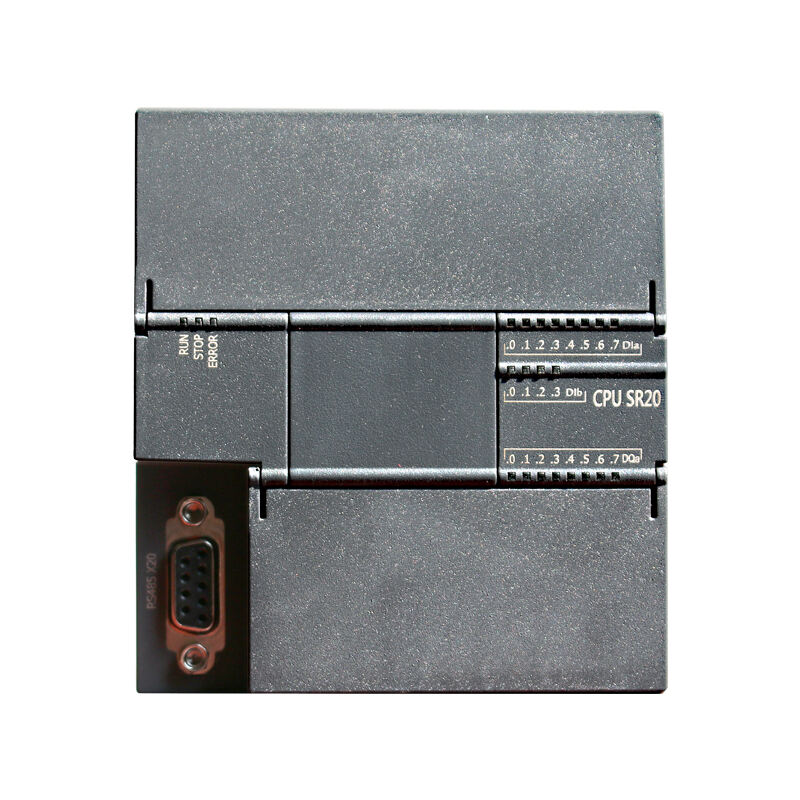

PLC SR20: Compact Control for Small-Scale Applications

The PLC SR20 is a versatile and compact solution specifically designed for small-scale automation projects. Its standout feature is the 12 input and 8 output configuration, ideal for environments where simplicity and efficiency are crucial. Moreover, the PLC SR20 boasts a basic instruction execution time of 0.15 µs, making it one of the quickest in its class. For instance, its efficient processing capability can be particularly beneficial in applications like packaging lines or simple processing units, where rapid response times are essential. Capable of networking with other automation devices via its Ethernet interface, this product PLC SR20: Standard PLC Module offers small businesses a robust and reliable option for enhancing their automated systems.

PLC SR30: Enhanced I/O Capacity for Medium Complexity Systems

For systems requiring more extensive process control, the PLC SR30 elevates the possibilities with an increased I/O capacity, providing 18 inputs and 12 outputs. This expansion caters to medium complexity systems, allowing businesses to efficiently handle more demanding automation tasks. A quintessential example of its implementation can be witnessed in assembly line optimizations and warehouse sorting mechanisms, where the higher input-output capacity ensures precise control over numerous variables. The PLC SR30 integrates seamlessly with other systems through a standardized Ethernet interface, supporting various industry protocols. Thus, the PLC SR30: Standard PLC Module emerges as a comprehensive solution for industries aiming to scale their operations efficiently.

PLC SR40: High-Density Configuration for Industrial Processes

In scenarios where large-scale industrial automation is key, the PLC SR40 empowers businesses with a high-density I/O configuration, offering 24 inputs and 16 outputs. This model is particularly suited for handling intricate process controls, as seen in operations like high-speed manufacturing lines and robust material handling systems. Equipped with capabilities for multiple high-speed pulse outputs and complex communication protocols like PROFINET, it ensures seamless machinery coordination and process optimization. Implementing PLC SR40: Standard PLC Module in such environments leads to significant improvements in operational efficiency and reliability.